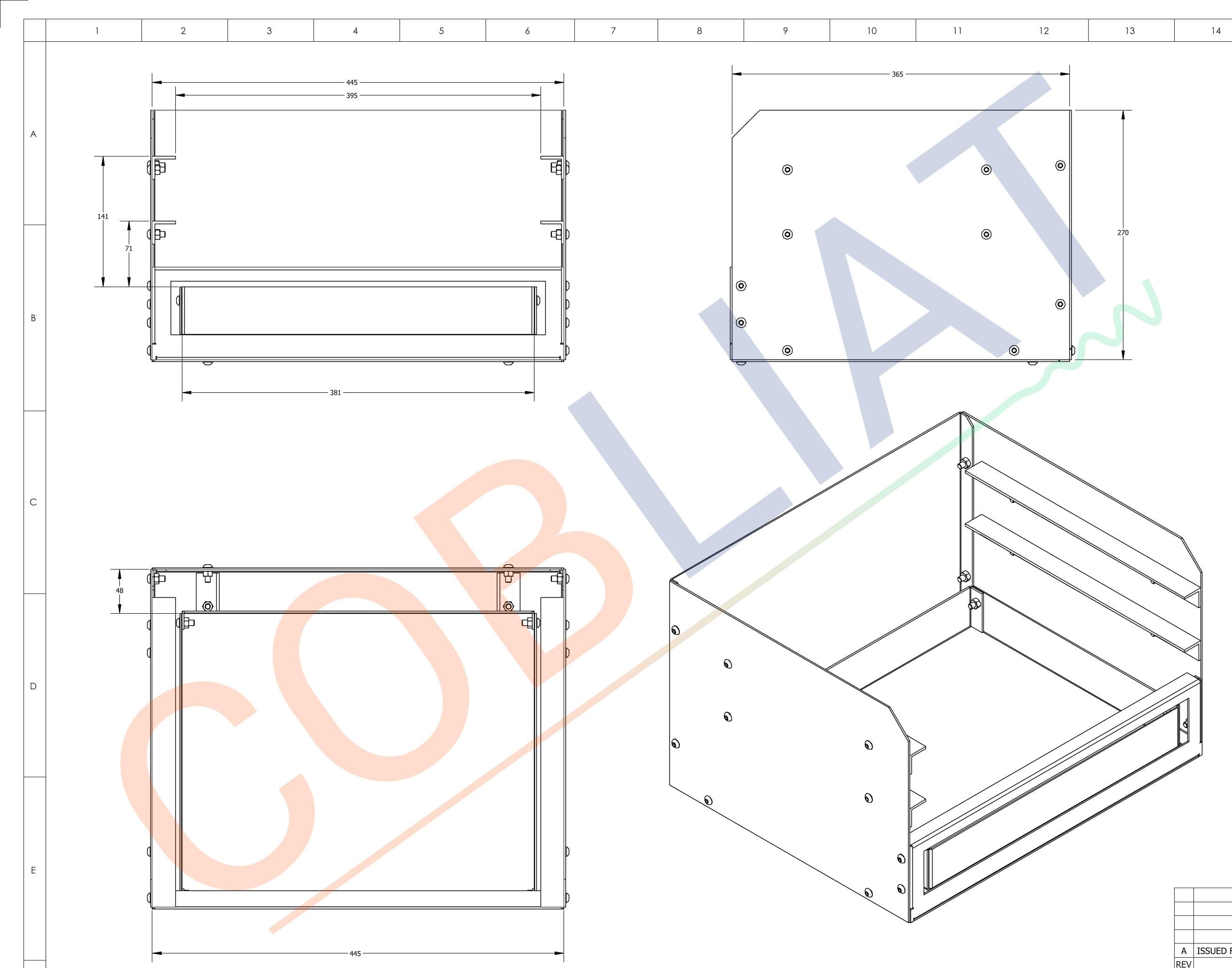

This project involved the design and drafting of a custom-made Sheetmetal Braai/BBQ for outdoor use. The client desired a durable and aesthetically pleasing braai constructed from ASTM A240 Grade 304 stainless steel to withstand high temperatures and outdoor conditions without corrosion. Given the client's limited access to welding equipment, a key challenge was to design the braai using exclusively bolted fasteners. Ensuring all fasteners were easily accessible for both assembly and future maintenance posed a significant design consideration. The project commenced with an initial consultation where the client expressed their vision and shared a single photograph of a braai/BBQ whose design they admired. Based on this input, we generated several concept designs and presented them to the client for selection. Following client feedback, we developed a comprehensive General Arrangement (GA) drawing. This stage involved incorporating client feedback and refining the design to meet their specific requirements. Subsequently, we produced detailed fabrication drawings, providing precise dimensions and specifications for each component. This project successfully delivered a complete set of fabrication drawings for a robust and functional Sheetmetal Braai/BBQ that met the client's requirements while adhering to their constraints regarding welding and assembly. July 2024, Price range ±R1000, Project duration 1-7 days

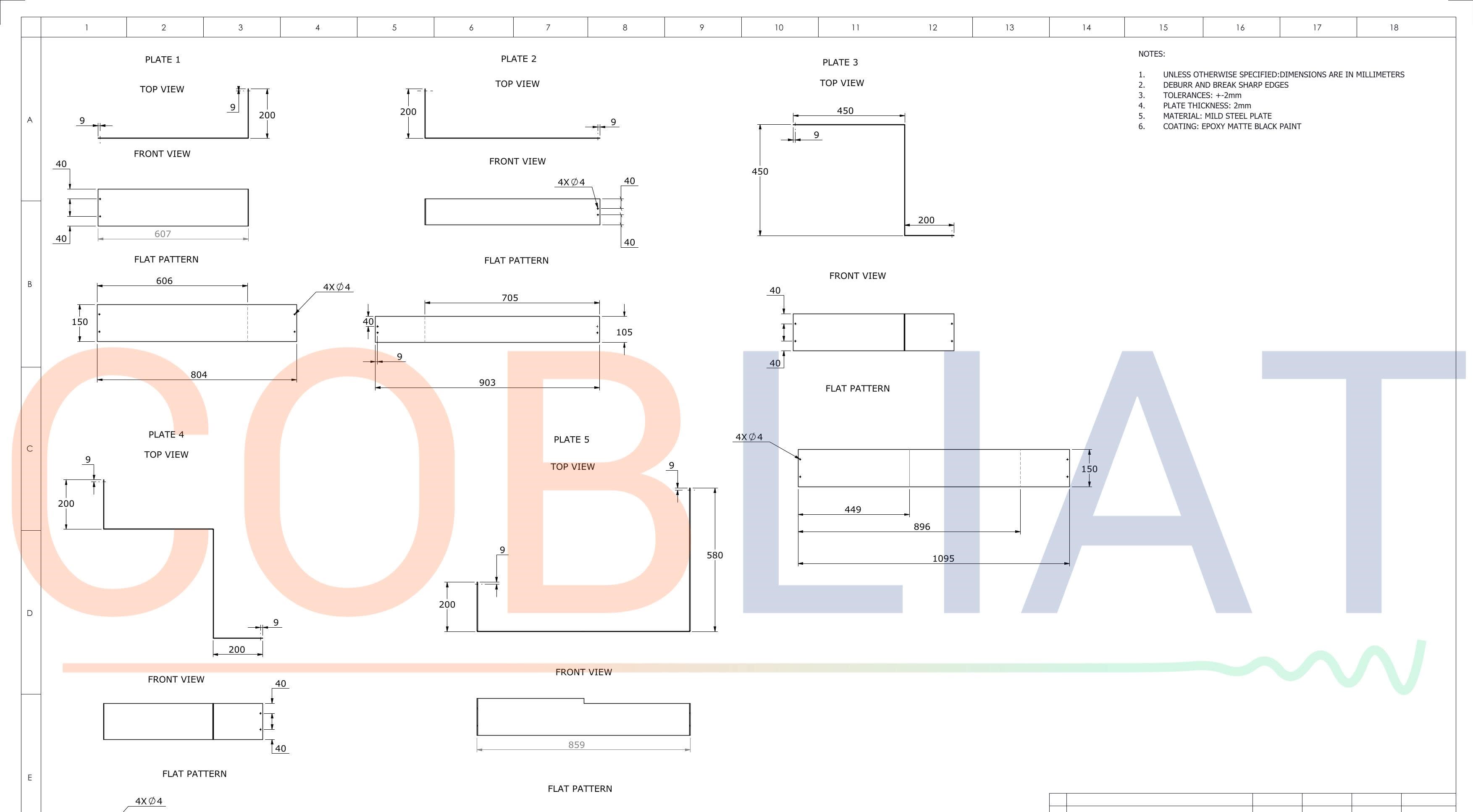

This project involved designing a set of custom-made plates to cover the bottom of a client's kitchen cupboards. The client sought a solution that was both aesthetically pleasing and practical, requiring minimal on-site modifications. To achieve this, we closely collaborated with the fabricator to ensure the design was not only visually appealing but also manufacturable using laser/plasma cutting and bending techniques. This approach streamlined the production process and reduced costs. Furthermore, we prioritized minimizing the number of individual plates to expedite installation and reduce labor costs. To ensure accuracy, we maintained consistent communication with the client, gathering precise cupboard dimensions and conducting a video call to verify measurements and clearances. This meticulous approach ensured that the final design perfectly matched the client's existing kitchen setup. Throughout the project, we faced the challenge of balancing aesthetic appeal with manufacturing constraints. We successfully navigated this challenge by carefully considering the design and material choices, ensuring the plates were both visually appealing and easily fabricated. The result was a set of five custom-designed plates that seamlessly integrated with the client's kitchen while meeting their requirements for aesthetics, functionality, and ease of installation. September 2024, Price range ±R1000, Project duration 1-7 days